Thermal Imaging

What is Thermal Imaging?

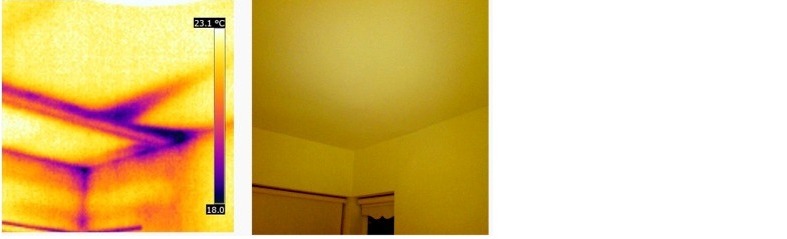

Thermal Imaging technology identifies weaknesses not visible to the naked eye. In a building envelope, thermal imaging surveys can help identify energy loss (heat in winter, cold in summer) due to poor insulation. This can apply to old homes as well as new. When such problems have been recognised then a suitable solution can be

identified.

Benefits of Thermal Imaging

Enables us the ability to see things that are not visible to the naked eye Highlights the extent at which the heat is lost Identifies defects that are present that are not visible.

Thermal Imaging Surveys are fast and focused. Once armed with the report, decisions can be made on the corrective action to be taken, maximising time and money!

Common defects found by Thermal Imaging

![]() Insulation defects in roofs and floors

Insulation defects in roofs and floors

![]() Defects in underfloor heating and radiators – leaks / blockages

Defects in underfloor heating and radiators – leaks / blockages

![]() Air leakage around penetrations (pipes etc.) in building envelope

Air leakage around penetrations (pipes etc.) in building envelope

![]() Cold Bridging

Cold Bridging

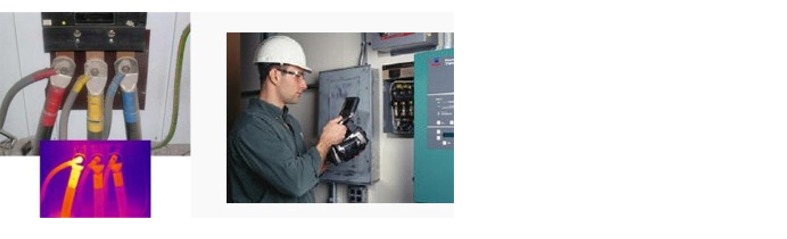

![]() Electrical vaults in fuse boards etc.

Electrical vaults in fuse boards etc.

Infrared Training Centre (ITC) Level 1

SC Air Tightness & Ventilation are ITC Level 1 Certified Thermographers. Infrared Thermography Certification is a written proof of our professional infrared qualifications. When training with ITC for Infrared Thermography Certification, you are attaining certification from the world's leading infrared training organisation. ITC infrared certification verifies the thermographer’s ability to operate an infrared camera, collect quality data, produce professional infrared inspection reports, and understand the techniques and limitations of infrared thermography for specific applications.

ITC Infrared Thermography Certifications are globally recognised and are designed to exceed the requirements of international infrared certification standards.

Infrared Testing Applications

SC Air Tightness & Ventilation perform thermal imaging in a variety of situations to detect problems before they become much larger issues. Some examples of the inspections we perform are as follows:

Roofing - Infrared testing is used to detect water damage & leaks beneath the surface of the roof allowing the opportunity repair the section before it continues to spread.

Electrical - Infrared testing is used as a means to detect potential circuit overload or areas of unusually high electrical resistance, allowing electricians to repl

ace the circuit before failure, eliminating costly downtime or further damage to the electrical system.

Preventative Maintenance - Plant maintenance technicians use infrared testing as a form of preventive maintenance by monitoring a variety of machine parts. By evaluating a machine's temperature signatures when in normal operating conditions, one can perform periodic infrared inspections to detect overheating joints, bearings, etc. in order to avoid costly downtime. This kind of preventative or predictive maintenance is critical to increasing & maintaining plant efficiencies.

Building diagnostics - Infrared testing is used to detect heating & cooling loss or moisture problems due to insulation deficiencies or construction issues.